The 2015 version of WHMIS incorporated the Globally Harmonized System (GHS) into Canada’s hazard communication framework. At that time, workplaces were required to complete the transition by December 1, 2018.

Since then, WHMIS has continued to evolve. In December 2022, the Hazardous Products Regulations (HPR) were amended to align Canada with the 7th revised edition of GHS (and some provisions of the 8th). These updates came into force in early 2023, with a transition period until December 14, 2025.

That means employers, suppliers, and workers now need to prepare for new requirements affecting classification, labels, and Safety Data Sheets (SDSs).

Does GHS replace WHMIS? Does WHMIS cease to exist?

The answer: WHMIS remains Canada’s national system. GHS is a global standard for classifying and communicating chemical hazards. Canada adopts GHS principles into WHMIS so that hazard information is consistent worldwide.

Until 2015, we used WHMIS 1988 (sometimes called the “old WHMIS”). WHMIS 2015 was the first major update to integrate GHS. The latest 2023 amendments are the next step, ensuring WHMIS stays aligned with global best practices.

What Is WHMIS?

WHMIS is a Canadian system for classifying hazardous products and communicating information to people using the products via labels, training and material safety data sheets. It helps ensure that every worker who comes in contact with chemicals understands the hazards posed by chemicals they work with and other essential information.

What Is GHS?

GHS is a global system. Given how many chemical products cross international borders every day, having a global system is essential. Basically, it helps ensure that we all understand/interpret the chemicals and hazardous materials in the same way.

What’s Changed With WHMIS 2015?

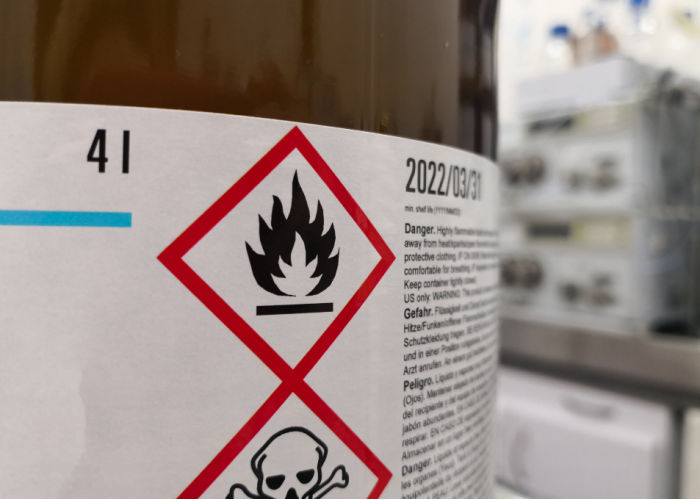

For 2015, WHMIS has aligned with the worldwide hazard communication system known as GHS – the Globally Harmonized System of Classification and Labelling of Chemicals. Aligning with GHS provides many benefits, including:

- Hazard classification criteria are more comprehensive which improves ability to indicate severity of hazards.

- New hazard classes are included.

- Physical hazard criteria are consistent with the Transport of Dangerous Goods (TDG regulations).

- Standardized language (hazard and precautionary statements).

- Standardized SDS format and more comprehensive requirements.

WHMIS symbols will be changed and referred to as pictograms.

What’s Changed Since 2023? (Important Update)

The 2022/2023 amendments to the HPR introduced additional updates:

-

New hazard classes/categories:

-

Chemicals Under Pressure (new physical hazard class).

-

Non-flammable Aerosols (Category 3).

-

Sub-categories for Flammable Gases (1A and 1B).

-

-

Revised Safety Data Sheet requirements:

-

Expanded information in Section 9 (Physical & Chemical Properties), including viscosity, particle characteristics, vapour density, etc.

-

Clearer disclosure of ingredients and concentration ranges.

-

-

Transition period:

-

From December 15, 2022 – December 14, 2025, suppliers and employers may follow either the previous or amended HPR.

-

After December 15, 2025, compliance with the amended regulations is mandatory.

-

Importantly, you cannot mix elements of both systems — you must follow one version in full.

-

What Do Employers Need To Do?

The deadline to comply with the amended HPR is December 14, 2025.

Employers should:

-

Obtain updated SDSs and labels from suppliers.

-

Educate and train workers on the new hazard classes and SDS elements.

-

Update their WHMIS program documentation before the deadline.

-

Ensure they are compliant with their provincial/territorial occupational health and safety laws.

During the transition period, you may receive products classified under either system. To protect workers, training must cover both formats until the transition is complete.

What Are Suppliers’ Duties Under WHMIS?

Suppliers (including manufacturers and importers) must:

-

Correctly classify hazardous products based on the latest HPR criteria.

-

Provide compliant labels and up-to-date SDSs.

-

Incorporate new hazard classes and SDS elements introduced by the 2023 amendments.

By December 15, 2025, all suppliers must provide products fully compliant with the amended HPR.

What Are Employers’ Duties Under WHMIS?

When a hazardous product is used in the workplace, employers are required to:

- Educate and train workers on the hazards and safe use of products.

- Ensure that hazardous products are properly labeled.

- Prepare workplace labels, as needed.

- Prepare SDSs, as necessary (e.g., if an employer manufactures a hazardous product that is used on-site).

- Provide access to up-to-date SDSs to workers.

- Ensure appropriate control measures are in place to protect the health and safety of workers.

What Are Workers’ Duties Under WHMIS?

Workers will participate in WHMIS education and training programs, take necessary steps to protect themselves and their co-workers, and participate in identifying and controlling hazards.

What Happens When An Inspector Visits The Workplace?

Inspectors have the authority to ensure that occupational health and safety legislation is being followed.

For WHMIS, for example, employers should be prepared to:

- Demonstrate that a WHMIS program is in place.

- Show where the SDSs are for the hazardous products used at that workplace.

- Show that hazardous products in use have the appropriate labels.

- Show education and training records for employees who work with or may be exposed to a hazardous product.

Inspectors may need to speak to workers to confirm that education and training has taken place. Workers should be able to answer these questions for every hazardous product they work with:

- What are the hazards of the product?

- How do I protect myself from those hazards?

- What do I do in case of an emergency?

- Where can I get further information?

Where Do I Start?

Here’s one way to plan your transition to WHMIS 2015. Remember, even if a product is exempt from a requirement to have WHMIS labels or SDS, it’s still your duty, as employer, to provide education and training to ensure safe use, proper procedures and storage.

1. Get To Know The New WHMIS + GHS.

Many chemical manufacturers in the U.S. and worldwide are already using GHS-compliant product labels. The GHS adds many benefits, including:

- Hazard classification criteria are more comprehensive which improves ability to indicate severity of hazards.

- New hazard classes are included.

- Physical hazard criteria are consistent with the Transport of Dangerous Goods (TDG regulations).

- Standardized language (hazard and precautionary statements).

- Standardized SDS format and more comprehensive requirements.

As mentioned, it helps ensure that we all understand/interpret the chemicals and hazardous materials in the same way.

Keep the WHMIS 2015 transition timeline in mind so you can plan accordingly.

2. Inform Others In The Workplace

Any workers who may come into contact or handle chemicals will need to be briefed or trained on GHS. What they need to know depends on their responsibilities.

For example:

- Management may need to be reminded of its legal obligations, and will likely want to see an implementation strategy, especially if you’ll be requesting additional resources.

- The joint health and safety committee or safety representative will want a briefing so that they can respond to workers’ questions.

- If you train in house, then your WHMIS trainers will need updates on training requirements and timelines.

- Workers will need training on GHS SDSs, especially if GHS-compliant products are already entering your workplace.

The more your train proactively, the smoother the transition will be.

3. Ensure Your Workplace Is WHMIS Compliant

You’ll have an easier time converting to WHMIS 2015 if your current WHMIS program is already running smoothly. While you’re assessing the status quo, eliminate from your inventory any products no longer used or needed, and substitute non-hazardous products for hazardous. Ask managers about any upcoming production changes that may affect your workplace’s WHMIS or GHS program.

4. Review Training Processes And Materials To Determine:

- What needs to be changed

- What you need to make the changes

- Whether there are better (i.e., faster, more economical) ways to provide training, such as combining classroom training with e-learning

- Who will make the changes

- When to make the changes.

- Consider budget implications. How will the conversion affect your training budget? If you provide training in house, what will it cost to update the training? Will you have enough trainers, especially during the grace period when you may be providing both WHMIS and GHS training? What costs will be involved in shifting from MSDSs to SDSs? Do you have enough administrative support?

- Draft an implementation schedule and budget. Involve key stakeholders and build 50% more time than you think you will need into the schedule.

- Get official input and buy-in from the key decision-makers at the design stage so that you’re ready to act when the time comes.

How We Can Help?

Our WHMIS is now being offered in our online store. By taking the course you’ll get a complete understanding of the GHS updates to WHMIS. The main changes revolve around new labels and some naming conventions.

Our course consists of 6 modules:

- Module 1: Overview of WHMIS

- Module 2: Hazard Classification

- Module 3: Labels

- Module 4: Safety Data Sheets

- Module 5: Exposure to Hazardous Products

- Module 6: Education and Training

By the end of the course, trainees will be able to:

- Explain the purpose of WHMIS

- Describe the changes under WHMIS

- Explain the building blocks of the classification system

- Name the elements of a hazardous product label

- Find information on a safety data sheet